Hello,

See her active society, I like that!

I have problem with tool changer on weeke BP12. I go this machine recently with damaged disc and migth some problems after restore. T60 as absolute 0 point works just fine, but if I try tool change, than it show error "Neg, software limit switch".and stops on N550 execution line.

Here are things what I check:

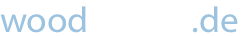

1) Tool in T11 as you see in picture is 80mm. Should work fine.

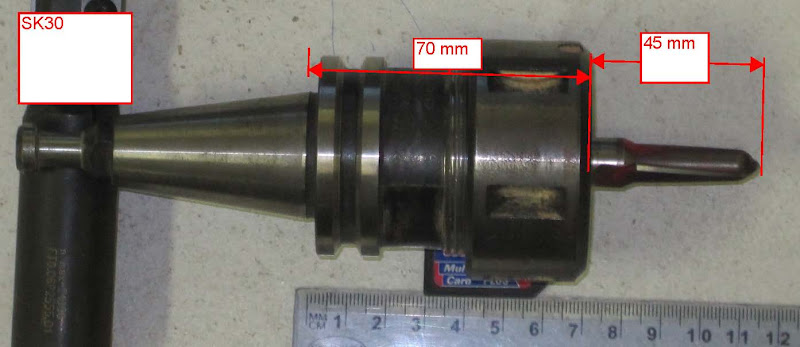

2) Z axis in T1 file is 115,2, fits with reality.

I dont see any mechanical reason why router receive such Z-axis value.

Please help, our local weeke service is not helping much with old machines.

Pictures

https://picasaweb.google.com/Viesturs.Kriskalns/ZaxisErrorSetup#

See her active society, I like that!

I have problem with tool changer on weeke BP12. I go this machine recently with damaged disc and migth some problems after restore. T60 as absolute 0 point works just fine, but if I try tool change, than it show error "Neg, software limit switch".and stops on N550 execution line.

Here are things what I check:

1) Tool in T11 as you see in picture is 80mm. Should work fine.

2) Z axis in T1 file is 115,2, fits with reality.

I dont see any mechanical reason why router receive such Z-axis value.

Please help, our local weeke service is not helping much with old machines.

Pictures

https://picasaweb.google.com/Viesturs.Kriskalns/ZaxisErrorSetup#